GROUND LOOPS

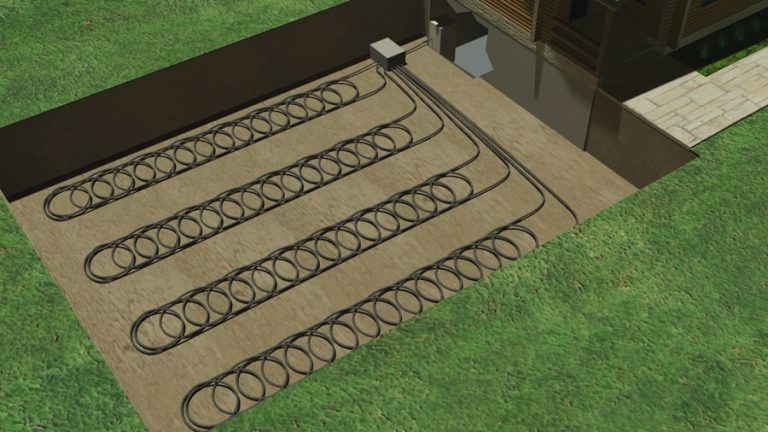

Horizontal Loop

A horizontal ground loop is one of the most commonly installed ground loop types. It is achieved by burying thousands of feet of pipe in trenches or a pit-style excavation. The pipe is buried at a depth of 6-8 feet to provide adequate frost protection. A large amount of land is needed to run those trenches, but if that land is available, it can be an easy and economical way of building a ground loop.

The size of the loop and amount of trenching needed are dependent on things like your heating load need and soil type.

The heating load will be the greatest factor in the sizing of the loop, and obviously the larger the house, the larger the heating load, the larger the ground loop needed to supply that heat.

Soil type is also a very important point to consider because some soils, like gravel and dry sand, don’t provide as good of a heat conductor as soils like wet dirt, clay, or static water.

Many times horizontal loops are installed as “Slinky Loops” because of the large amount of pipe and trenching required for a horizontal loop

Slinky Loops

A slinky loop is a variation of the horizontal ground loop and is used to maximize the effective heat transfer area of the excavation. The slinky loop gets its name from tying the pipe into large coils that overlap each other, allowing for large lengths of pipe to fit into much smaller trenches. For example, 800 ft. of ¾ in. pipe can be tied into a Slinky loop with 3 ft. diameter coils and be buried into a trench that is only 150 ft. long.

Slinky loops may be a little more economical than down and back horizontal loops because less trenching may be required, but more piping is needed for the same heating capacity. They area also easier to install because they don’t kink when putting them down in the trenches, and won’t spring up off the bottom of the trench.

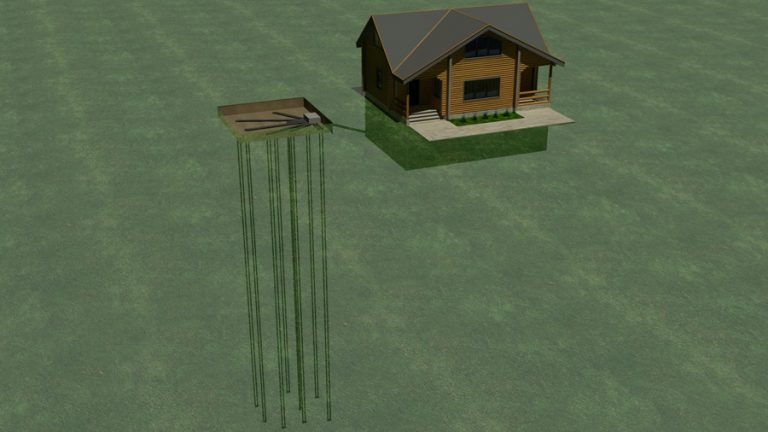

Vertical Loop

A vertical loop is another variation of the closed ground loop and is installed by drilling vertical boreholes 100 to 300 feet down into the ground, and putting a loop of pipe down it. When the pipe is in, a special thermal-conductive grout is pumped into to ensure uniform contact with the earth, which ensures efficient heat transfer between the earth and the ground loop.

This method is typically more expensive to install than other methods, because of the large amounts of vertical drilling, but is very effective in situations where land is limited.

The size and number of loops in a vertical system is mainly dependent on the heating load needed, as well as static water level and the type of soil it will be drilled through.

Having a well driller that has experience in drilling thermal bore holes, not just wells, is very important.

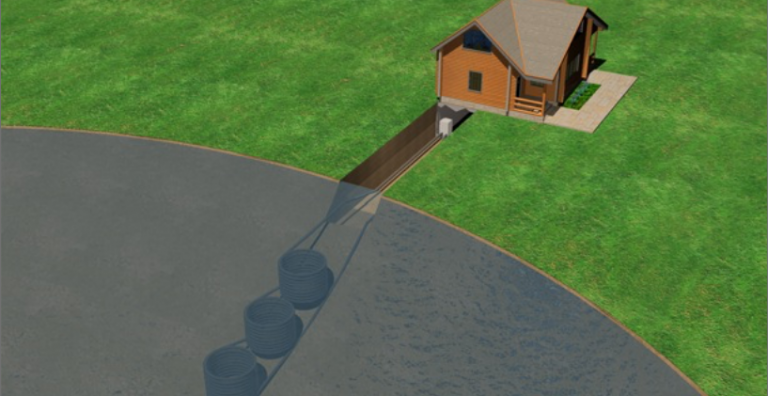

Pond Loops

A pond loop is another closed ground loop for a geothermal system, except instead of trenching or drilling holes, large coils of tubing or a purpose built heat exchanger is submerged in a local body of water, like a pond or a lake. This makes the water of the pond the heat exchanger of the system.

This method is a great option if there is a sufficiently sized pond close to the structure, because there is very little trenching and excavation needed. Because of that it can be very cost effective to install this system over another type.

The size of the loops on this ground loop will need to take into account more things than the standard earth ground loop.

Things like pond size, depth and flow will also come into play along with the standard heat load of the house and flow through the pipes.

Other considerations also need to be taken with a pond system. It will significantly affect the temperature of the pond all year around, making it colder in the winter when heat is being sucked out, and warmer in the summer when heat is being put back in. This can affect any fish or wildlife that inhabit the pond, so precautions need to be taken. Also local water use permits and zoning requirements may be required, depending on your location.

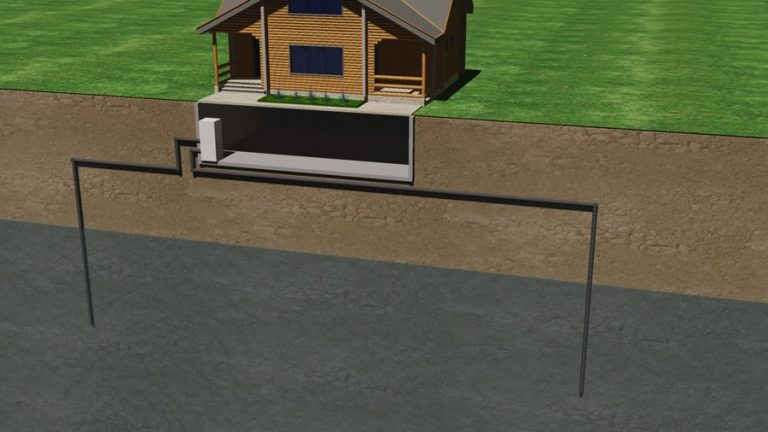

Open Loop

An open loop system (aka ‘pump and dump’ loop) is simply pumping water from a well or pond through the heat exchanger, and then discharging it back into the ground.

The most common open loop system involves two wells; one that sucks the water up to the heat pump, and the other expels it back into the ground. No water is used up or harmed in any way during this process; it is just pumped through a system that adds or removes a few degrees of heat, then returned to its source.

These types of systems are known as open loop because the supply and discharge are not connected. An open loop system is the least expensive to install compared to the other loop types provided there is sufficient ground water available in the area. It is even more ideal if there is an existing well feeding the property, because that could be the supply well, and only one more needs to be drilled to be the discharge well.

Open Loop systems are the least expensive to install and have the highest efficiencies of any ground loop

Open loop systems also have greater performance than closed loop systems, because no heat is being constantly removed from one volume of earth, so incoming water temperatures are just the temperature of the aquifer, and remain constant throughout the year.

Scaling of the heat exchanger is another issue to take into account, because constantly running hard mineral water through the system can be an issue. There are specially built cupro nickel heat exchangers that prevent much of this, and should be used on any geothermal heat system that uses an open ground loop.